Measurement-while-drilling (MWD) aims at collecting accurate high-resolution information from the production blast hole drills with a target of characterization of highly variable sub-surface excavations.

Measurement-while-drilling (MWD) aims at collecting accurate high-resolution information from the production blast hole drills with a target of characterization of highly variable sub-surface excavations.

The energy market for MWD demands high accuracy with low short-term and long-term drifts sensors. For many applications the solution of Open Loop MEMS accelerometer does not provide enough accuracy, while suggested electro-mechanical accelerometers with higher accuracy are too big, expensive, and require high power consumption.

Physical Logic has developed MEMS Closed Loop accelerometer to fit MWD challenging system requirements. Based on our current design of our well known MAXL-CL-3000 series, we have introduced some modifications to achieve high accuracy measurements under high temperature. While keeping Long-Term Bias Repeatability as low as 500µg and Long-Term Scale Factor Repeatability of 400 ppm, we ensure successful drilling applications for the energy market.

High temperature measurements of 125ºC and up to 150ºC

The new Closed Loop MEMS accelerometers series is designed for high temperature measurements of 125ºC and up to 150ºC. Reliability and accuracy under harsh conditions are translated into excellent bias performances under vibration while still complying with the same specifications as our standard MAXL-CL-3000 series.

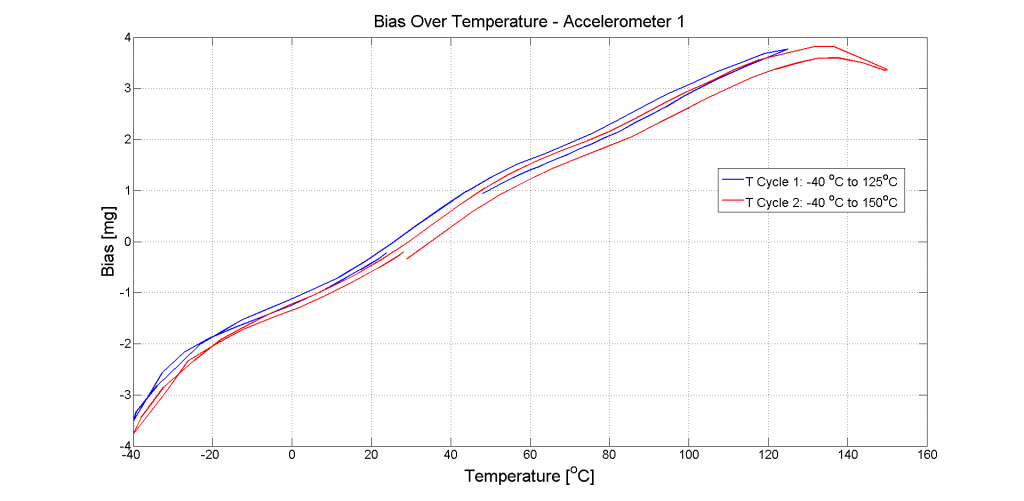

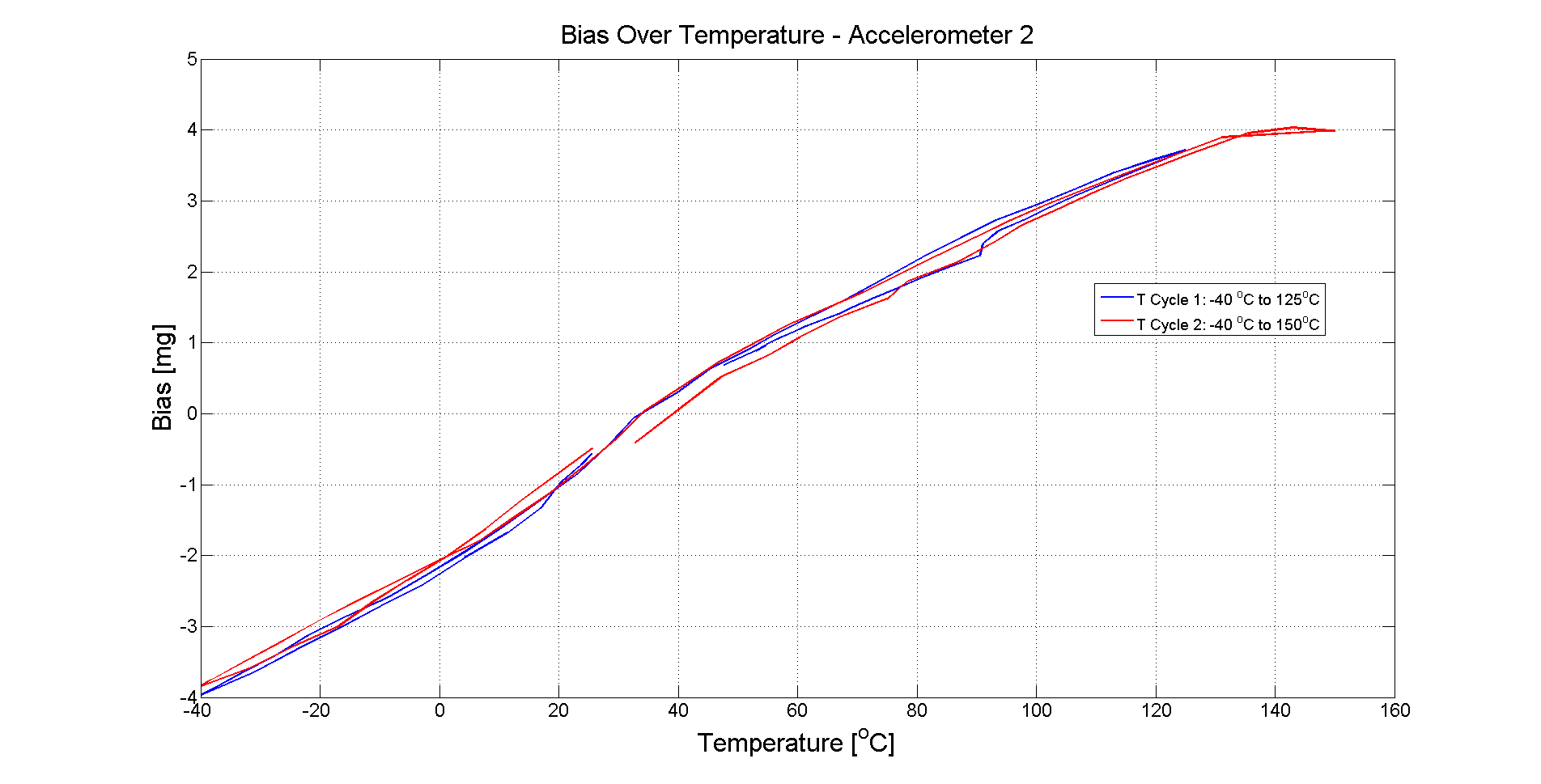

In this report we present first test results of bias over temperature cycles that were taken on first Closed Loop MEMS prototypes. Figure 1 and Figure 2 show Residual bias over temperature of 2 out of the tested accelerometers. In this test a temperature cycle from -40 ºC to 125 ºC was applied, followed by a second cycle between -40 ºC to 150 ºC.

Our next step to be presented soon will show test results of performance under combination of temperature and vibration cycles in HALT oven; this is to illustrate the MWD work environment. The HALT tests to be presented will be part of our NPI steps for qualification of the new accelerometer to production.