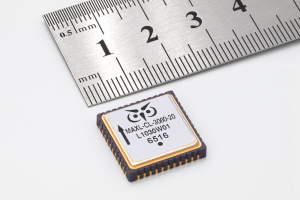

Our closed loop MAXL-CL-3030 ΔΣ (sigma-delta) MEMS accelerometer provides improved performance, such as scale factor linearity, bias stability and vibration rectification.

It is a fully integrated sensor enclosed in a specially designed and manufactured LCC44 package.

Closed Loop MEMS Products

MAXL-CL-3015

- Sensing range: ±15 g

- One year Bias repeatability: <500 μg

- One year Scale Factor repeatability: <400 ppm

Applications

- Inertial Navigation

MAXL-CL-3030

- Sensing range: ±30 g

- One year Bias repeatability: <500 μg

- One year Scale Factor repeatability: <400 ppm

Applications

- Inertial Navigation

MAXL-CL-3050

- Sensing range: ±50 g

-

One year Bias repeatability:

<1200 μg - One year Scale Factor repeatability: <400 ppm

Applications

- Inertial Navigation

MAXL-CL-3060

- Sensing range: ±60 g

-

One year Bias repeatability:

<1200 μg - One year Scale Factor repeatability: <400 ppm

Applications

- Inertial Navigation

MAXL-CL-3070

- Sensing range: ±70 g

-

One year Bias repeatability:

<1200 μg - One year Scale Factor repeatability: <600 ppm

Applications

- Inertial Navigation

MEMS Device

Our Closed-Loop is produced using the same proprietary and proven process flow which we successfully developed for the Open-Loop accelerometer.

However, the closed loop MEMS is equipped with an actuator mechanically and electrically isolated from the sensing part.

ASIC

Our ASIC is a sophisticated mixed signal system on chip (SOC) that has been specially designed for our closed loop accelerometer.

The key blocks on the ASIC are: an analog front-end (AFE) block to perform capacitance-to-voltage conversion, an N-bit analog-to-digital converter (ADC), a digital electronic filter block to perform ΔΣ modulation and phase compensation as well as a feedback driver blocks to generate the rebalance force on the proof mass.

Operating Principal

The capacitive MEMS sensor is displaced from its equilibrium position when it experiences an external acceleration. This results in a corresponding capacitance change in the sensor which is converted and amplified into a voltage signal via the AFE block. The amplified analog signal is oversampled and converted into digital signal by the ADC block, and then passed to the digital electronic filter block for further signal processing. After the digital ΔΣ modulation and phase compensation, a single-bit bit-stream is generated and applied as a feedback to the sensor through the driver blocks. The feedback control signal restores the MEMS sensor back to its equilibrium position, minimizing the mechanical displacement of the proof mass. The described concept makes possible a significant improvement in the linearity and vibration rectification of the sensor.

To ensure an effective shaping of the quantization noise created by the single-bit comparator, 4-th order ΔΣ modulation is implemented. A careful system design ensures a stable closed loop, and the concept of mixed signal ASIC enables more flexibility in the choice of control parameters and improve their preciseness.

Compact Packaging

We offer a specially designed LCC44 ceramic packaging. In our proprietary assembly process, the MEMS and ASIC chips are fabricated separately and integrated into the package. The interface between the MEMS, ASIC and the package is utilized by wire bonding. Our package is RoHS compliant.